Busbar Bending Machine 5 Smart Buys & 3 Mistakes to Avoid

A busbar bending machine is a specialized tool used to bend copper or aluminum busbars into the desired shapes and angles for use in electrical panels, switchgear systems, and distribution boards.

Busbars are flat metallic strips that carry large amounts of current, and they need to be shaped precisely to fit inside control panels and connect safely to other components. The busbar bending machine makes this possible by bending the metal bar without cracking, twisting, or damaging it.

Types of Busbar Bending Machines:

1. Manual Busbar Bending Machines

These machines are operated by hand or basic hydraulic pressure. They’re simple and cost-effective but rely on the operator’s skill.

- Easy to use for basic bends

- Suitable for low-volume jobs

- Manual adjustment for angle and position

- Lower accuracy compared to CNC machines

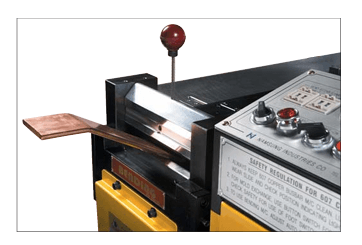

2. Hydraulic Busbar Bending Machines

Hydraulic bending machines use hydraulic force to bend busbars with greater power and consistency.

- Can handle thicker copper/aluminum bars

- Offers smoother and more accurate bends

- Often includes an angle measuring gauge

- Can be operated with a foot pedal for hands-free control

3. CNC Busbar Bending Machines

CNC stands for Computer Numerical Control. These are automated machines designed for high-precision, high-speed production.

- Programmable angles and batch operations

- Accurate, repeatable bending with minimal human error

- Saves operator time and reduces material waste

- Can handle complex, multi-directional bends

Key Features of Quality Busbar Cutting Machines:

Clean, burr-free cuts (to avoid damage or resistance in connections)

Adjustable cutting dies to suit various bar sizes

Safety enclosures and foot-pedal controls

Compatibility with bending and punching units (in combined systems)

CNC models may include:

Touchscreen controls

Batch programming

Material length detection

Automatic feeding systems

Why Smart Buying Matters

In today’s fast-moving world of electrical panel building, accuracy, speed, and reliability are a must. That’s why buying a busbar bending machine isn’t just another purchase — it’s a big decision that affects your panel quality, work speed, and overall safety.

As a trusted supplier of busbar processing machines in the UAE and GCC, we’ve helped many panel builders, OEMs, and contractors choose the right equipment for their needs. But we’ve also seen some companies make expensive mistakes by choosing the wrong machine or not thinking it through.

In this article, we’ll share 5 smart tips to help you pick the right busbar bending machine — plus 3 common mistakes to avoid. Whether you’re just starting or looking to upgrade, this guide will help you make a smart, confident, and profitable decision.

Smart Buys When Choosing a Busbar Bending Machine

1. Choose CNC for Precision and Repeatability

Manual machines might seem cheaper upfront, but CNC-controlled busbar benders offer unmatched accuracy, repeatability, and efficiency. Especially for high-volume switchgear production, CNC systems ensure consistent results, minimal material waste, and reduced labor fatigue.

Smart Buy Tip: Look for CNC models with digital angle input, auto-calibration, and multi-axis control for complex bends.

2. Invest in a Multi-Function Machine

If you’re looking to cut, bend, and punch busbars — a combined machine can save significant floor space, reduce setup time, and streamline workflow.

Smart Buy Tip: Check for integrated bending/cutting/punching stations with quick tool change features.

3. Verify the Machine’s Busbar Capacity

Not all machines can handle every busbar size. Ensure the machine supports your required copper/aluminum bar sizes, typically up to 12mm thick and 160mm wide.

Smart Buy Tip: Look for adjustable dies and hydraulic bending strength suitable for low-voltage and medium-voltage applications.

4. Prioritize After-Sales Support and Spare Parts

Buying from a local or regional authorized supplier in the UAE or GCC ensures faster service, quicker delivery of spare parts, and on-site training options.

Smart Buy Tip: Choose suppliers with trained service teams and available spare parts in the region.

5. Check for Safety and Operator-Friendly Features

Don’t overlook safety! A well-designed busbar bender should have protective enclosures, foot pedals, emergency stops, and ergonomic controls.

Smart Buy Tip: Ask about CE certification, overload protection, and built-in safety mechanisms.

Common Mistakes to Avoid

1. Ignoring Machine Compatibility With Production Volume

Many buyers underestimate their production needs. Choosing a small-capacity or manual bender for a high-volume shop leads to bottlenecks and delays.

Mistake to Avoid: Don’t under-buy. Think long-term — estimate daily output, future scaling, and new project types.

2. Focusing Only on Price, Not Value

Many buyers underestimate their production needs. Choosing a small-capacity or manual bender for a high-volume shop leads to bottlenecks and delays.

Mistake to Avoid: Don’t under-buy. Think long-term — estimate daily output, future scaling, and new project types.

3. Not Testing or Requesting a Demo

Many buyers skip the opportunity to see the machine in action before buying. That’s a big risk — especially when working with imported or unfamiliar brands.

Mistake to Avoid: Always request a live demo or video walkthrough to understand functionality and user interface.

Why Buy from a Trusted Supplier in the UAE/GCC?

As an authorized regional supplier of top-tier brands like Namsung (Korea), we bring more than just machines — we deliver value through:

- Installation & operator training

- Fast delivery across UAE, KSA, Qatar, and other GCC regions

- Technical support and maintenance contracts

- Availability of genuine spare parts

- Expert consultation based on your application