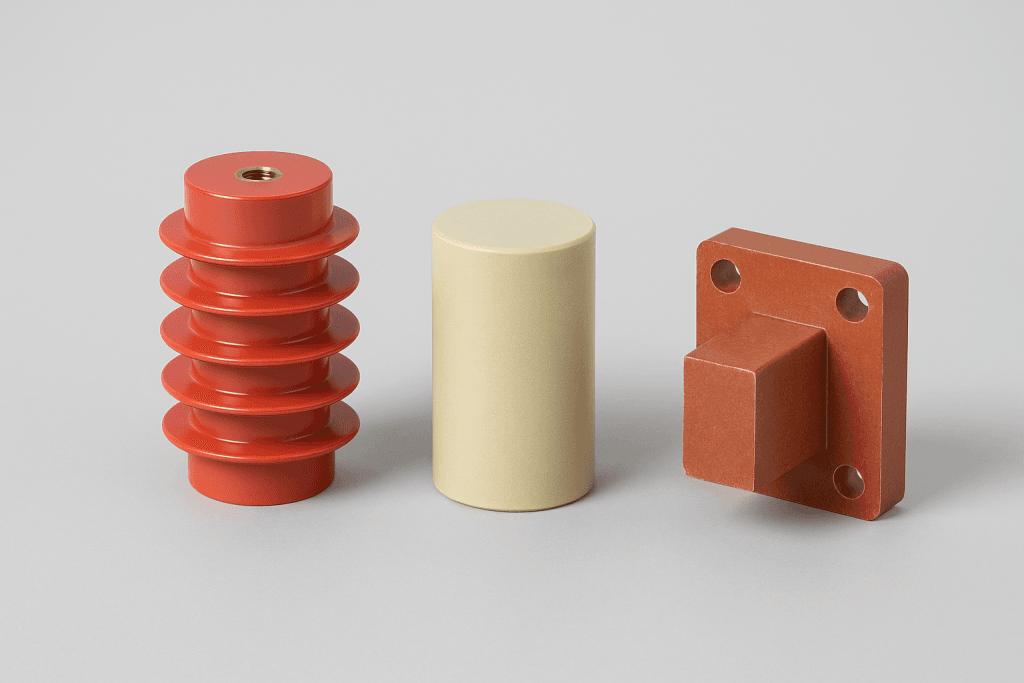

FRP Epoxy and SMC Insulators Backbone of Modern Switchgear

FRP Epoxy and SMC Insulators insulators are specialized materials used to electrically isolate different conductive parts within switchgear assemblies, preventing unwanted current flow and electrical faults. Each of these materials brings unique properties that make them indispensable in high-performance electrical equipment.

FRP Epoxy and SMC Insulators

In the world of electrical power distribution and automation, the role of insulators is critical to ensure operational safety, system reliability, and long-term durability. Among the latest innovations in insulation technology, FRP (Fiber Reinforced Plastic), Epoxy, and SMC (Sheet Molding Compound) insulators stand out as essential components in modern switchgear systems.These high-performance insulating materials are transforming the way electrical switchgear is designed and built—offering unmatched strength, excellent dielectric properties, and superior resistance to extreme environments.

These high-performance insulating materials are transforming the way electrical switchgear is designed and built—offering unmatched strength, excellent dielectric properties, and superior resistance to extreme environments.

Understanding the Modern Need FRP Epoxy and SMC Insulators

Switchgear systems are at the heart of every electrical distribution network, whether in industrial plants, commercial buildings, or utility stations. As the demand for compact, efficient, and high-capacity systems increases, so does the need for insulation materials that can perform under stress while maintaining safety and stability.

Traditional materials like porcelain or glass, though reliable, are gradually being replaced by FRP Epoxy and SMC Insulators due to their:

- Higher mechanical and electrical strength

- Lightweight composition

- Resistance to heat, flame, and chemicals

- Easy integration in compact switchgear designs

Types of Insulators and Their Role in Switchgear

The main types used in modern switchgear include FRP (Fiber Reinforced Plastic), Epoxy Resin, and SMC (Sheet Molding Compound) insulators. Each of these materials offers unique mechanical and dielectric properties suitable for low and medium voltage applications.

1. FRP Insulators (Fiber Reinforced Plastic)

FRP insulators are manufactured by reinforcing thermoset plastic with fiberglass, creating a composite material that combines low weight with high strength.

Benefits

- High tensile and flexural strength

- Excellent insulation and mechanical performance

- Resistant to UV, weathering, and corrosion

- Ideal for busbar supports and structural components in LV/MV switchgear

2. Epoxy Insulators

Epoxy resin-based insulators are known for their high dielectric strength and resistance to tracking and arcing. Their molding flexibility allows for customized shapes and complex geometries.

Application Include

- Medium-voltage (MV) circuit breaker components

- Transformer bushings

- Post and bushing insulators in both indoor and outdoor switchgear

3. SMC Insulators (Sheet Molding Compound)

SMC is a composite material made from fiberglass-reinforced polyester resin, which is compression-molded into insulating components.

Advantages

- Flame-retardant and non-hygroscopic

- High dimensional stability under load

- Uniform surface finish for precision applications

- Used in low and medium voltage electrical panel components

Why These Insulators Are Ideal for Modern Switchgear

Modern switchgear systems are becoming smarter, smaller, and more demanding in performance. Insulators used in these systems must meet several critical requirements:

- Compact design adaptability: FRP and SMC insulators are ideal for tight enclosures.

- Thermal endurance: Withstand temperature variations without degradation.

- Mechanical integrity: Maintain shape and strength under electrical and mechanical loads.

- Electrical safety: Provide complete insulation between live components and metal frames.

By using FRP Epoxy and SMC Insulators, switchgear manufacturers can ensure greater reliability, enhanced safety, and a longer lifespan of their systems—even in harsh industrial environments.

Why These Insulators Are Ideal for Modern Switchgear

At AL Mayar MJ, we follow international quality standards such as IEC, ANSI, and ISO during the production of all types of insulators. Our facility uses:

- Precision molds and CNC machining for dimensional accuracy

- Advanced curing ovens for epoxy and FRP materials

- Rigorous electrical and mechanical testing on all insulators

Each insulator is designed for durability, high insulation performance, and safe operation in various low and medium voltage applications.

Applications Across Industries

Our FRP Epoxy and SMC Insulators are widely used in:

- Low Voltage and Medium Voltage Switchgear Panels

- Control Panels and Distribution Boards

- Transformers and Busbar Systems

- Capacitor Banks and Substations

- Renewable Energy Infrastructure

Their performance and flexibility make them suitable across industrial, commercial, and utility applications.

Conclusion: Shaping the Future of Power Distribution

As electrical systems continue to evolve, the components within them must also rise to meet new challenges. FRP, Epoxy, and SMC insulators are not just replacements for outdated materials—they are reliable, cost-effective, and future-ready solutions that form the foundation of modern switchgear systems.

At Mayar MJ, we are proud to be at the forefront of this innovation. Our insulators are engineered with precision, tested for excellence, and trusted by switchgear manufacturers and engineers across the globe.